Aerosol Valves and Actuators: Enhancing Convenience and Efficiency

Welcome to a world where convenience meets efficiency – the world of aerosol valves and actuators. These seemingly small components play a vital role in our everyday lives, making our interactions with aerosol products seamless and effortless. Whether we’re using deodorants, air fresheners, or paints, we owe our convenience to these innovative solutions.

Aerosol valves are responsible for regulating the flow of the product, controlling the release of a fine mist or foam. On the other hand, actuators are the triggers, the interface between our fingers and the valve, allowing us to dispense the desired amount with precision.

Designed with precision engineering, aerosol valves and actuators are the ultimate embodiment of efficiency. Through innovative design and technology, these components ensure that every spray, every dose, is consistent and precise, providing optimal convenience for consumers.

In this article, we will explore the world of aerosol valves and actuators, diving into their functionality, different types available, and the impact they have on product performance. Join us as we discover the magic behind these unassuming yet essential components enhancing our daily lives.

What are aerosol valves and actuators?

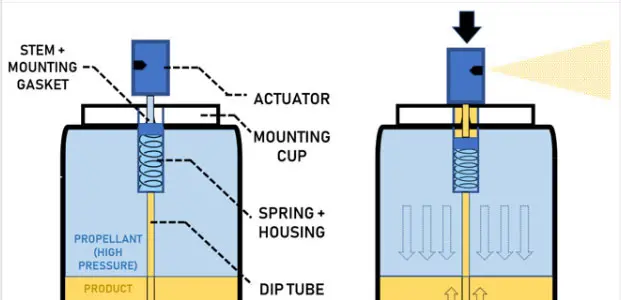

Aerosol valves and actuators refer to essential components in aerosol packaging systems. The aerosol valve, typically made of metal or plastic, controls the release of the aerosol product by creating a seal that prevents leakage. It is connected to the container and has several key components, including a stem, spring, and gasket. The stem is pushed down by the actuator, allowing the product to be dispensed when the valve is open. Actuators, on the other hand, are the part that is pressed or pushed by the user to activate the valve and release the aerosol content. They come in various designs and sizes to suit different applications and user preferences. Actuators not only allow for precise control of the spray pattern and intensity but also play a role in ensuring safety by incorporating child-resistant mechanisms or tamper-evident features. Overall, aerosol valves and actuators are crucial for delivering the desired amount of product in a controlled manner, making them integral to the functionality of aerosol packaging systems.

How aerosol valves and actuators work

How aerosol valves and actuators work can be explained by understanding the mechanisms involved in their operation. When the user presses down on the actuator, it depresses the stem of the valve, which opens a passage for the aerosol product to be released. The pressure inside the container forces the product to travel through the stem and out of the valve. However, when the user stops pressing the actuator, the spring inside the valve pushes the stem back up, closing the passage and preventing any further release of the product. This ensures that the aerosol container remains sealed and prevents leakage or accidental discharge. The design of the actuator influences the spray pattern, intensity, and overall user experience. Some actuators have additional features, such as a locking mechanism, which prevents accidental activation during transportation or storage. By understanding how aerosol valves and actuators work together, it becomes evident how they facilitate the controlled dispensing of aerosol products.

Benefits of using aerosol valves and actuators

Benefits of using aerosol valves and actuators can be observed in various aspects of aerosol packaging systems. Firstly, these components ensure precise control over the dispensing of aerosol products. By incorporating a valve and actuator system, manufacturers can provide users with the ability to regulate the amount of product dispensed, resulting in reduced wastage and optimal usage. Additionally, aerosol valves and actuators play a significant role in ensuring safety. Child-resistant mechanisms integrated into the design help prevent accidental activation by young children, minimizing the risk of exposure to potentially harmful substances. Furthermore, tamper-evident features on the actuator provide an extra layer of protection, assuring consumers that the product is in its original state and has not been tampered with. Moreover, aerosol valves and actuators enable a controlled spray pattern and intensity, allowing users to apply the product precisely and evenly, enhancing convenience and user experience. Overall, the utilization of aerosol valves and actuators not only enhances the functionality and safety of aerosol packaging systems but also contributes to efficient usage and improved consumer satisfaction.

Common applications of aerosol valves and actuators

Common applications of aerosol valves and actuators are found in a wide range of industries and products. One of the most common applications is in personal care and household products, including aerosol sprays such as deodorants, hair sprays, and air fresheners. These valves and actuators allow for controlled dispensing of the product, ensuring that the desired amount is applied without wastage. Another significant application is in the automotive industry, where aerosol valves and actuators are utilized in products such as car lubricants, cleaners, and foams. The precise control provided by these components allows for targeted application and even coverage, promoting efficient usage. Additionally, aerosol valves and actuators are used in the pharmaceutical industry for nasal sprays, inhalers, and topical creams, enabling precise and controlled medication delivery. In the food industry, aerosol valves and actuators are employed in products like cooking sprays and whipped creams, ensuring accurate spraying and dispensing. These components also find applications in the agricultural sector for pesticides and fertilizers, as well as in industrial settings for paints, coatings, and adhesives. The versatility and adaptability of aerosol valves and actuators make them indispensable in various industries, allowing for efficient and controlled product dispensing in a wide range of applications.

Factors to consider when choosing aerosol valves and actuators

Factors to consider when choosing aerosol valves and actuators are crucial for ensuring optimal performance and compatibility with the specific application. One important factor is the type of product being dispensed. Different products may have unique characteristics, such as viscosity or compatibility with certain materials, which can impact the selection of valves and actuators. It is essential to choose components that can withstand the pressure and chemical properties of the product to prevent leakage or degradation. The desired spray pattern and intensity also play a role in the decision-making process. Some applications may require a fine mist, while others may need a wider spray or a concentrated stream. The design of the actuator, including the shape and size of the nozzle or spray button, should be considered based on the desired spray characteristics. Additionally, factors such as container material, size, and shape should be taken into account to ensure proper fitting and compatibility with the valves and actuators. Lastly, the aspect of safety should not be overlooked. Depending on the application, it may be necessary to consider child-resistant features, tamper-evident mechanisms, or other safety measures to protect users and prevent unauthorized access. By carefully considering these factors, one can select aerosol valves and actuators that meet the specific requirements of the application, ensuring optimal performance and user satisfaction.

Conclusion

Fanxun has more than 10 years of industry experience, focusing on packaging and aerosol can systems. We provide professional services to all our valued customers, shipping to over 30 countries

Depending on your needs and production system, you will find the aerosol can and accessories that best suit your needs. At Fanxun, you can choose from a number of options designed by the best experts who will strive to package your product with precision and care to make your product stand out in the market.