Aerosol valfleri gündelik ürünleri düşündüğünüzde aklınıza gelen ilk şey olmayabilir, ama hayatımızın birçok alanında önemli bir rol oynuyorlar. Bu isimsiz kahramanlar çok çeşitli aerosol ürünlerinin tedarikinden sorumludur, sprey boyadan arabalara, kozmetiklerden ev temizleyicilerine ve hatta tıbbi inhalerlere kadar uzanan ve sektörde son derece başarılı cihazlardır.. Bu yazıda aerosol valfleri dünyasına derinlemesine bir dalış yapacağız, Çalışma yöntemlerine göre kendiniz için doğru aerosol valfini seçin, endüstri uygulamaları, özellikler, vesaire.

Aerosol valfi nedir?

Aerosol valfleri sıvıların salınımını kontrol eden küçük ama önemli ve kritik bileşenlerdir, sis veya sprey formundaki gazlar veya ince katılar. Sprey boyalarda yaygın olarak kullanılır, deodorantlar, oda spreyleri, yağlayıcılar, ve diğer ürünler. Birkaç temel bileşenden oluşurlar, kök dahil, konut, daldırma tüpü, ve aktüatör. Bu küçük ama kritik ekipman parçaları, sıvıların kontrollü salınımında önemli bir rol oynamaktadır., Basınçlı kaplardan çıkan gazlar veya ince katılar, Ürünü tutarlı ve kullanıcı dostu bir şekilde sunmak için uyum içinde çalışan bileşenlerle. Çünkü valf ürünü eşit şekilde püskürtecektir, tamamı kullanıcının elleriyle kontrol ediliyor, diğer avantajların yanı sıra. Endüstride popüler bir ürün oldular, 1950'lerden günümüze ev aletleri ve diğer endüstriler

Aerosol valfi nasıl çalışır?

Bir Aerosol Valfi bir aerosol veya aerosol ürününü serbest bırakmak için kullanılan bir cihazdır, genellikle bir basınçlı kapta bulunur, sprey kutusu veya aerosol şişesi gibi. Bu valflerin çalışma prensibi, basınç ve sıvı akışını içeren basit bir fiziksel prosese dayanmaktadır.. Aerosol valfi şu şekilde çalışır:

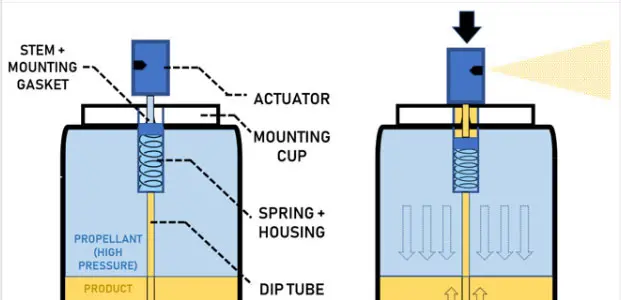

Aerosol kutusunun kullanım öncesi ve kullanım sırasındaki gösterimi

- Kaptaki sıvı veya gaz: Aerosol ürünleri genellikle bir sıvı karışımı içerir., gaz veya katı parçacıklar. Bu ürünler kapalı bir kapta muhafaza edilmektedir., ve ürünü valfe itmek için genellikle kabın içinde belirli bir miktarda basınç vardır..

- Valf yapısı: Aerosol valfleri genellikle birkaç önemli parçadan oluşur, valf kafası dahil (aktüatör), valf çekirdeği (valf gövdesi), sızdırmazlık contası (conta veya O-halkası) ve meme. Valf başlığı kullanıcıyla temas halinde olan kısımdır, valf çekirdeği anahtar işlevine sahip bir parçadır, sızıntıyı önlemek için sızdırmazlık contası kullanılır, ve nozül sıvının püskürtme şeklini kontrol eder.

- Basınç tahliyesi: Kullanıcı valf kafasına bastığında veya tetiklediğinde (sprey düğmesi gibi), valf çekirdeği açılır, kaptaki basıncın serbest bırakılmasına izin vermek. Serbest bırakılan bu basınç, sıvıyı veya gazı nozuldan atmosfere doğru iter..

- Sıvı dispersiyonu: Nozulun özel tasarımı ve yapısı sayesinde, sıvı veya gaz, küçük parçacıklar veya aerosol halinde belirli bir şekilde dağıtılır. Bu dağılım genellikle tekdüzedir, kontrollü üretmek, ince sprey.

- Kullanıcı kontrolü: Kullanıcılar valf kafasını çalıştırarak spreyin yoğunluğunu ve yönünü kontrol edebilir. Bu, hassas ürün uygulaması ve kullanım kolaylığı sağlar.

- Sızdırmazlık: Valf içindeki sızdırmazlık contası, ürünün kullanılmadığı zamanlarda sızıntı yapmamasını veya buharlaşmamasını sağlar.. Bu, ürünün tazeliğinin korunmasına ve israfın önlenmesine yardımcı olur.

Aerosol valf uygulamaları:

Birçok türü var aerosol valfleri, Birçok endüstri ve üründe anahtar rol oynayan; hemen hemen her sektörde kullanılabilirler, ve piyasadaki birçok ürünün gerekli bir parçasıdırlar. Pek çok sektörü kapsadığı için, hepsini listelemek imkansız. İşte sektördeki bazı ortak ana uygulama alanları::

- Kişisel bakım ürünleri: Kozmetik ve kişisel bakım ürünleri endüstrileri sıklıkla aerosol valfleri kullanır. Aerosol parfümlerde kullanılırlar, deodorantlar, saç jelleri, tıraş köpükleri ve diğer ürünler. Aerosol valfi eşit bir, tam olarak dağılmış sprey, ürünün kullanımını kolaylaştırmak.

- Ev ürünleri: Ev temizlik ürünleri, oda spreyleri, böcek öldürücüler, vesaire. ayrıca ürünleri doğru şekilde püskürtmek ve dağıtmak için sıklıkla aerosol valfleri kullanır, ev işlerini daha rahat hale getirmek.

- Eczacılık ürünleri: Aerosol valfleri farmasötik alanda astım ve diğer solunum yolu hastalıklarını tedavi etmek için inhaler yapmak amacıyla kullanılır.. Bu valfler, ilacın hastanın ihtiyacına göre doğru dozda ve kontrollü olarak salınmasını sağlar..

- Otomotiv ürünleri: Yağlayıcı, fren temizleyici, Lastik şişirici ve diğer ürünler, araç bakım ihtiyaçlarını karşılamak üzere ürünü doğru bir şekilde uygulamak ve dağıtmak için genellikle aerosol valfleri kullanır..

- Gıda endüstrisi: Gıda sektöründe de aerosol valf kullanan bazı ürünler bulunmaktadır., yemek pişirme sprey yağı gibi, yemeklik yağ püskürtücüler ve krem şanti püskürtücüler.

Aerosol valf uygulamasının genel özelliklerini anladıktan sonra, ihtiyaçlarınıza göre doğru pazar teknolojisini seçebilirsiniz.

Aerosol valfinin özellikleri nelerdir?

Aerosol valfi spesifikasyonlar, bir aerosol valfinin spesifik teknik parametrelerini ve performans özelliklerini ifade eder. Bu özellikler genellikle üreticiler tarafından sağlanır, böylece tüketiciler ve işletmeler kendi ihtiyaçlarına uygun bir aerosol valfi seçebilirler.. Aerosol valf spesifikasyonları tipik olarak aşağıdakileri içerir:

- Vana türleri: Ana aerosol valf türlerini açıklama, püskürtme valfleri gibi, köpük vanalar, dağıtım vanaları, vesaire.

- Kapasite: Aerosol valfinin her spreyi tarafından salınan sıvı veya gazın hacmi, genellikle mililitre veya saniyede mililitre cinsinden.

- Kalibre: Valf kafasının boyutu (aktüatör), genellikle milimetre cinsinden, spreyin dağılımını ve enjeksiyon açısını etkileyen.

- Püskürtme mesafesi: Aerosol valfinin sıvı veya gaz püskürtebileceği en uzak mesafe, genellikle milimetre veya fit cinsinden.

- Püskürtme modu: Aerosol valfinin sağladığı püskürtme modunu açıklayın, düzgün sprey gibi, ince sis, atomizasyon, sürekli sprey, nokta kaplama, vesaire.

- Malzeme: Vananın iç ve dış parçalarının malzemesini açıklayın, metal dahil, plastik, kauçuk veya diğer uygun malzemeler. Bunun nedeni, malzeme seçiminin sıvı veya gaz halindeki ürünün uyumluluğu ve kimyasal özelliklerinden etkilenebilmesidir..

- Püskürtme açısı: Aerosol valfinin püskürtme açısını açıklayın, yatay gibi, dikey, yelpaze şeklinde, vesaire.

- Basınç gereksinimleri: Sıvı veya gazın düzgün şekilde püskürtülmesini sağlamak için aerosol valfinin gerektirdiği basınç aralığını açıklayın.

Bu spesifikasyonlar uygun aerosol valfinin seçilmesinde önemlidir çünkü farklı uygulamalar farklı türde ve farklı aerosol valfi yetenekleri gerektirir.. Tüketiciler ve işletmeler genellikle ürünlerinin özel ihtiyaçlarına göre aerosol valfleri seçerler, Optimum performans ve güvenilirliği sağlamak için ortam ve performans gereksinimlerini kullanın. Üreticiler, müşterilerin doğru seçimi yapmasına yardımcı olmak için genellikle ürün belgelerinde veya resmi web sitelerinde ayrıntılı aerosol valfi teknik özellikleri bilgileri sağlar..

Aerosol Gövdeleri ve Gövde Contası Tipleri Nasıl Seçilir

Hatırlamak: valf gövdesi ve gövde contası, valfin contasını oluşturdukları ve dolayısıyla ürün kalitesini garantiledikleri için aerosolün önemli parçalarıdır. Yanlış tipte conta veya sap kullanılması büzülmeye neden olur, genişleme veya zayıf sızdırmazlık, ürün kaybına yol açan. Bu aksesuarları seçmeden önce, ürünlerinizin hangi sektörlerde kullanıldığını bilmelisiniz. Projenin başarısı ya da başarısızlığının üretici firma ile de belli bir ilişkisi vardır.. . Aşağıda uygun aerosol gövdesini ve gövde contasını seçmenize yardımcı olacak bazı öneriler sunacağım.:

- Ürün türünü anlayın: Birinci, Aerosol ürününüzün doğasını netleştirmelisiniz. Farklı ürün türleri, ürünün uygun şekilde dağılmasını ve püskürtülmesini sağlamak için farklı gövdeler ve contalar gerektirebilir.. Örneğin, kişisel bakım ürünleri, kimyasallar, veya temizlik ürünleri farklı gövde ve contalar gerektirebilir.

- Vana tipini belirleyin: Farklı türdeki aerosol valflerinin farklı gövde ve conta gereksinimleri olabilir. Örneğin, tek kullanımlık vanalar özel olarak tasarlanmış gövdeler ve contalar gerektirebilir, yeniden kullanılabilen valfler daha dayanıklı bileşenler gerektirebilirken.

- Ürün tutarlılığını ve viskozitesini göz önünde bulundurun: Ürün tutarlılığı ve viskozitesi mil ve conta seçimini etkileyecektir. Daha kalın ürünler, yüksek düzeyde aşınmayla başa çıkabilmek için aşınmaya daha dayanıklı gövdeler ve contalar gerektirebilir.

- Sıcaklık ve basıncı dikkate alın: Aerosol ürünlerinin kullanıldığı ortam, valf gövdelerinin ve contalarının performansını etkileyebilir. Yüksek sıcaklık veya yüksek basınç koşulları, güvenli ve güvenilir çalışmayı sağlamak için özel malzemeler ve gövde ve conta tasarımları gerektirebilir.

- Malzeme seçimi: Valf gövdeleri ve contaları genellikle plastikten yapılır, metal, kauçuk veya diğer malzemeler. Malzeme seçerken ürünün bileşimini ve onunla uyumluluğunu göz önünde bulundurun. Örneğin, bazı kimyasallar belirli malzemelerle uyumlu olabilir, diğer malzemeler dayanıklı olmayabilirken.

- Uyumluluk ve Standartlar: Seçilen gövde ve contanın kullandığınız aerosol valfiyle uyumlu olduğundan ve ilgili standart ve düzenlemelere uygun olduğundan emin olun..

- Kalite ve Dayanıklılık: Aerosol valf gövdeleri ve contalarının kalitesi ve dayanıklılığı çok önemlidir, özellikle ürünün uzun süre saklanması veya taşınması gerekiyorsa. Test edilmiş ve kanıtlanmış yüksek kaliteli bileşenlerin seçilmesi, ürün stabilitesini ve güvenilirliğini artırabilir.

Özetlee

Aerosol valfleri küçük olabilir, ama etkileri çok büyük. Çeşitli ürünlerin uygun ve kontrollü dağıtımını kolaylaştırırlar, hayatımızı kolaylaştırmak ve daha güvenli hale getirmek.

Bu yazıda aerosol valfinin ne olduğunu ve nasıl çalıştığını anlatacağız., uygulama endüstrisi spesifikasyonları, vesaire. İlgili ürünler hakkında bilgi almak için, daha fazla ürün bilgisi almak istiyorsanız, yapabilirsiniz bize Ulaşın veya ziyaret edin Fanxun tedarikçi platformu

Daha fazla aerosol valfi bilgisi

Aerosol Valfleri Küresel Pazar Raporu 2023