Manufacturing process and quality control of plastic lids

We are a lid production supplier next I’ll explain the manufacturing process of plastic lids involves multiple steps and quality control measures for the finished product, the following is an overview of the general manufacturing process and related quality control aspects:

Raw material selection:

Select suitable plastic materials for use in plastic lids, chẳng hạn như polyetylen (Thể dục), polypropylen (PP), vân vân. The raw material should meet the relevant quality standards and ensure its reliability and sustainability.

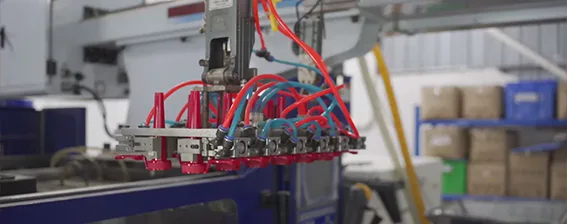

Injection molding:

Pre-prepared plastic pellets or granules are heated and injected into the mold through an injection molding machine. The injection molding process requires control of temperature, pressure and injection time to ensure the formation of uniform and firm plastic lids.

Mold design and manufacturing:

The design and manufacturing of the mold is critical to the quality and appearance of the plastic lids. The mold should have high precision and durability to ensure consistent size, shape and surface quality of the lid.

Cooling & Curing:

After injection molding, the plastic lid needs to be cooled and cured in the mold to ensure it retains its shape and strength.The plastic lids taken out of the injection molding machine may have residual material or burrs, which need to be sheared and deburred to make the edges of the lids smooth and conform to the requirements.

Inspection and testing:

Quality inspection and testing are performed on the produced plastic caps. Common testing items include dimensional inspection, appearance inspection, sealing performance test, vân vân. to ensure that the lids meet the required quality standards.Plastic caps that meet quality requirements are packaged and then properly stored and transported to maintain their quality and integrity.

Quality control plays an important role in the entire manufacturing process, including raw material inspection, injection molding process control, mold maintenance and overhaul, and finished product inspection. Key quality control measures may involve monitoring of temperature and pressure, use of dimensional measuring tools, sampling and inspection, and having a professional administrator to manage and record traceability.

Ngoài ra, our production process workers are very serious about product control not missing a single point so we produce products that comply with relevant standards and regulations, such as ISO 9001 quality management system and related industry specifications, which is also an important means to ensure the quality control of plastic lids. Please contact us to answer your questions if you have any needs