When it comes to packaging solutions, the importance of flip top cap design cannot be underestimated. Flip-top lids are versatile, convenient and, in many cases, the first point of interaction a consumer has with a product. Whether you are in the cosmetics, pharmaceutical or food and beverage industry, a well-crafted flip lid can make a significant difference in usability and aesthetics.

Flip Top Cap Design: The importance of sealing

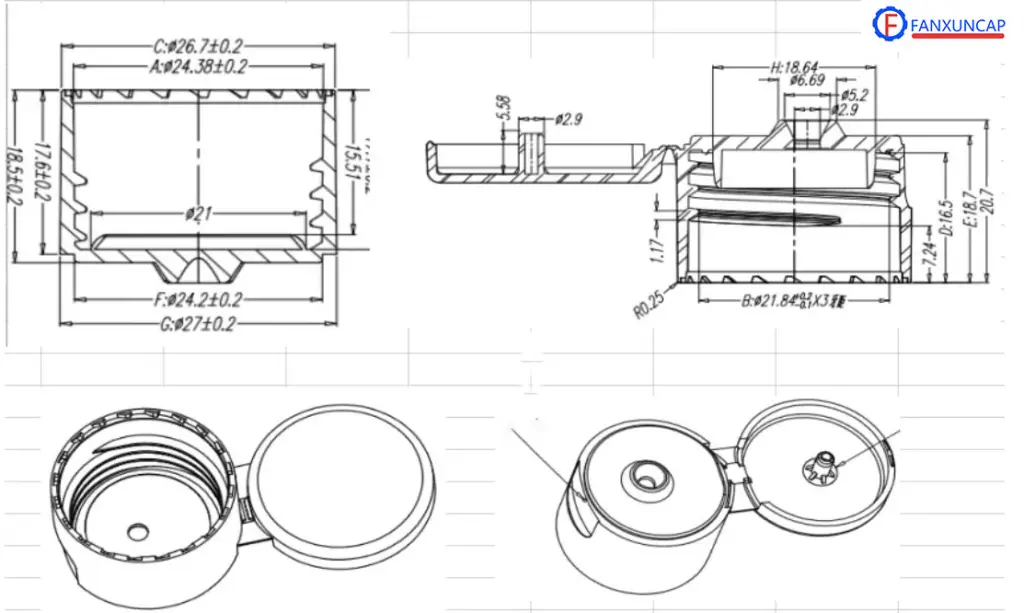

The flip seal assembly design includes a hinged lid that is hingedly attached to the bottom of the closure. It allows the lid to flip open and closed. The seal also includes some gaskets, which have the effect of forming a leak-proof seal between the lid and the container. The seal design must ensure that the lid is firmly fixed to the base to ensure a high-quality seal and prevent product spillage and leakage.

Plug seals are the simplest and most commonly used sealing systems. This seal fits inside the inside diameter of the bottle, where it will create surface contact. To ensure good assembly, the inner diameter of the bottle or can must be controlled

The most important first impression

El flip cover is not only a functional component but also a design element that contributes to the overall appeal of the product. It is the main point of user interaction, so proper design is crucial. A well-designed flip cover can make your product stand out on the shelf and enhance the user experience.

Bringing convenience and innovation to all walks of life

El flip top cap design is an innovative technology widely used in many different industries to improve product packaging and user experience. Whether you work in cosmetics, medicamento, alimento, or other industries, a clamshell design may be helpful for your products. Some applications in industries will be introduced below to better understand its importance.

- Cosmetics industry

In the cosmetics industry, aesthetics and branding play an important role. Not only does the flip cover need to be easy to use, it also needs to be consistent with the brand image. Considerations such as color, shape and materials are crucial. Luxury cosmetics brands may choose metallic or pearlescent finishes, while eco-friendly brands may prefer sustainable materials like bamboo or recycled plastic. - industria farmaceutica

En el campo farmacéutico, safety and security are of paramount importance. Medication flip-tops must be tamper-evident to ensure the integrity of the medication. Childproof design is often necessary to prevent accidental exposure by children. Además, easy-to-read labels are critical for patient compliance. - Industria de alimentos y bebidas

The food and beverage industry needs flip-top lids that are not only functional, but also capable of preserving the freshness of their contents. Considerations include the material’s ability to prevent leaks and contamination and its ability to be easily dispensed. Depending on the product, the cap may need to be resealable or tamper-evident for customer safety.

Why Customize Flip Cover

The key to a successful clamshell design is customization. While the basic concept of the clamshell remains consistent, its adaptation to different industries is where innovation thrives. Companies that offer customizable clamshell solutions can ensure that the design meets the unique needs of each industry.

Customization allows selection of materials, colores, sizes and special features based on your product and brand image. This flexibility ensures that your packaging stands out while meeting the necessary functional requirements. Since there are so many customization directions, we won’t list them all here. Here are the common customization directions.

Brand identity and differentiation

Custom clamshell designs offer unique opportunities for brand identity. By choosing colors that are consistent with your brand tone, unique shapes, and the integration of your brand logo, you can highlight your brand identity on your product packaging and enhance brand recognition. This helps the brand stand out in the market and attract consumers’ attention.

Meet product needs

Different products require different types of clamshell designs. Some products may require easy-to-operate flip-top lids, while others may require special safety features such as child safety locks. With a custom design, you can ensure that the clamshell design meets the specific needs of your product, improving its ease of use and performance.

Improve user experience

User experience is one of the key factors for product success. A clamshell design that is easy to open, close and use enhances user satisfaction and leaves a positive first impression. Usuarios’ satisfaction with packaging may influence their overall impression and loyalty to the product.

Comply with regulatory requirements

Different industries and products may face specific regulations and standards that require packaging to meet specific specifications. With a custom clamshell design, you can ensure your product packaging complies with regulations and avoid possible legal issues.

Improve product safety

Some products require additional security features, such as anti-counterfeiting or sealing properties, to ensure product integrity. With a custom design, you can integrate these security features to provide your customers with more confidence and security.

Why customize clamshell design? Because it provides an opportunity to differentiate your product packaging, emphasize brand features, improve product performance, meet regulatory requirements, enhance user experience, increase safety, and meet sustainability standards. Custom clamshell design is not just part of the product packaging, it is also one of the key factors in the success of the brand, giving the product a clear competitive advantage to meet the needs and expectations of modern consumers.